Rigorous Inspection Guidelines Ensure Consistent DLC Coating Quality

High Quality & Consistency

A key part of any organization is their quality control department. High quality consistent product is a necessity if a company is going to be successful. At TS NCT, we are constantly monitoring our products to ensure our customers that they are receiving the highest quality product in the industry. Part of our commitment to our customers is our ISO 9001 2000 certification. Our ISO certification ensures our customers that we are maintaining the highest level of quality control available in industry today. Embracing the ISO system has allowed TS NCT to provide our customers with the highest and most consistent product quality available.

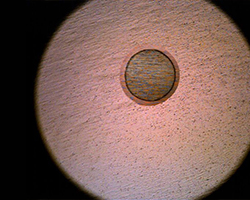

A calo test is performed in three areas of each fixture to check the PVD coating thickness and ensure a uniform consistent result. This test can measure each layer's thickness as well as the total thickness of the coating. This ensures that the customer is receiving a consistent film each time their product is processed.

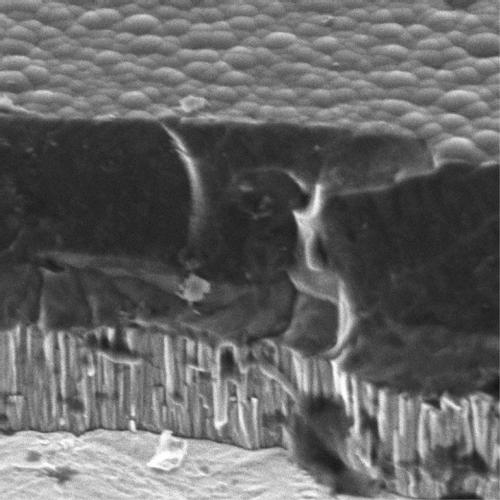

Metallography is used to measure the coating thickness and look at the interface of the coating and the substrate. It is also used to check the case depth of the nitride layer to ensure the desired case depth is achieved.

Scratch adhesion tests are performed on our PVD coatings to ensure optimum adhesion is being achieved.

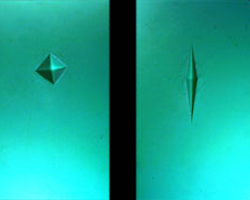

Microhardness tests are performed on the PVD coatings to ensure the proper hardness for each film is produced. Superficial hardness test are performed on the nitride layer to ensure the desired hardness for the material processed has been provided.

HV Indent (left) / Knoop Indent (right)

Rigid inspection guidelines are followed for all product entering and leaving NCT. Products are checked for any defects, surface impurities, prior surface treatments, burrs, or grinding damage in incoming inspection. Products are checked for coating consistency, uniform appearance, proper color and coating thickness in final inspection. If a print or coating specification is supplied, the product is checked against the specification or print to ensure all requirements are met.