Our world-class research team brings your ideas to life.

Our Research & Development staff applies state-of-the-art technology, innovative thinking and a practical approach to help make your product ideas a reality. Our tribologists can refine your new concepts and generate additional solutions to address problems with existing products that have been identified through real-world experience.

We specialize in developing custom solutions to meet your specific needs. We will work with you to select the proper surface finish, coating and PVD or PACVD coating process for all your applications—no matter how demanding their requirements.

Our research staff can develop custom solutions to meet your specific requirements, for even your most demanding applications. We will work with you to select the proper surface finish, coating and PVD or PACVD coating process for your application.

Our ability to deposit DLC and PVD coatings using cathodic arc, plasma-enhanced magnetron sputtering, or plasma-assisted CVD allows us to develop custom coatings or coating compositions to meet specific performance requirements. Our engineering team has developed coatings to combat friction, wear, fretting, erosion and corrosion. With the wide range of deposition processes available, our engineering staff can deposit the coatings at temperatures that will not affect your substrate.

Research engineers monitor the products during the coating process.

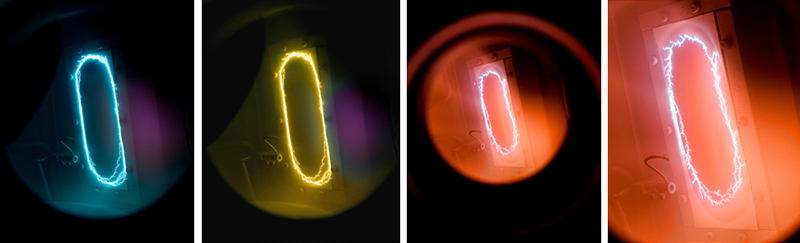

Cathodic Arc Coating

The photo at right (two shots on the left) shows a cathodic arc coating source as it is initially generated on the surface of the target material to be deposited.

The photos following on the right show a cathodic arc coating source as a reactive gas is introduced into the chamber. The color of the plasma plume will change depending on what reactive gas is introduced.

High-Energy Sputtering Sources

The photo to the right shows one of TS NCT’s high-energy sputtering sources that can be used to deposit our PVD coatings.

Additional Capabilities

In addition to our PVD/PACVD capabilities, TS NCT can provide ferritic nitrocarburizing, Melonite® QPQ of ferrous alloys, which can nitride inside surfaces uniformly. Nitriding processes have been developed for customer-specific applications, creating a case-hardened layer to perform in a targeted environment. Duplex processes can also be provided when the substrate experiences high loads and additional support is required for one of the PVD or PACVD coatings.

Our wide range of DLC coatings has solved many component failures. Our engineering staff will evaluate your applications and tailor our DLC coatings to meet your performance requirements. With our PEMS technology, multilayer DLC films can be deposited when a layered coating is required to meet performance requirements and improve the coating’s performance. With our CAM technology, we can deposit our standard DLC coatings at temperatures as low as 150 C with no degradation in film quality, and our engineering staff can develop processes at lower processing temperatures for specific applications. This allows our customers to choose from a wide range of substrate materials for their application.