Northeast Coating Technologies is now TS NCT

PART OF A GLOBAL LEADER IN HIGH-PERFORMANCE COATING SOLUTIONs

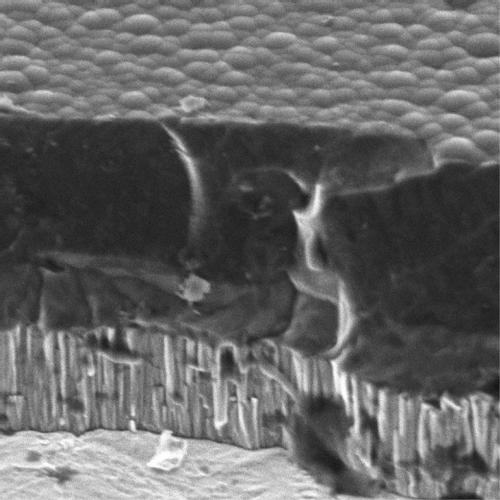

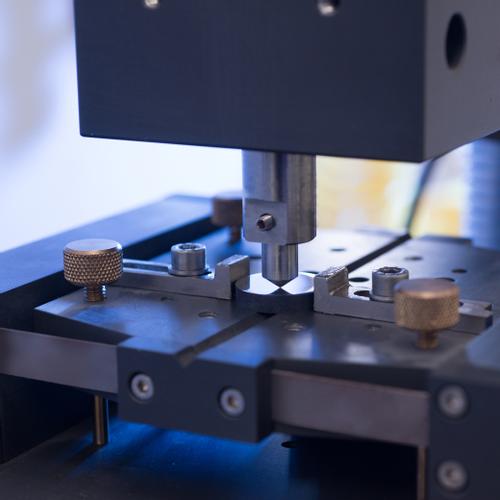

Now a full member of the HEF Groupe, we offer the latest in sophisticated technologies derived from HEF’s global research resources...plus our continued dedication to provide the cost-effective, on-time solutions your industry demands, from medical to aerospace to firearms and beyond.

LEARN HOW TS NCT CAN MEET YOUR NEEDS:

Contact Us -OR- (207) 985-3232

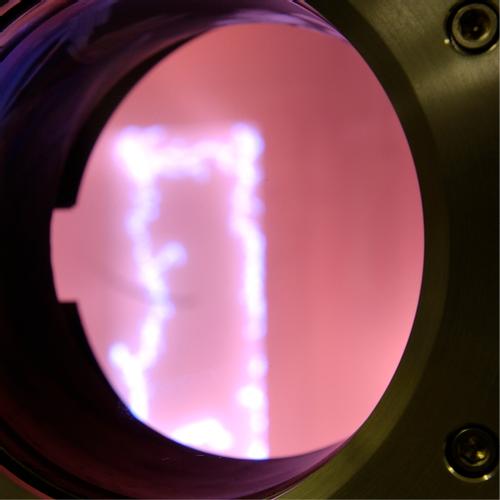

GET THE MOST ADVANCED COATINGS...

...FOR THE MOST DEMANDING INDUSTRIES...

...FROM TS/NCT: YOUR FULL-SERVICE SOURCE.