Finishing Process

The REM Isotropic Finishing process produces a uniform surface roughness reducing sliding friction. Utilizing a vibratory finishing process, the parts can be matched with proper media to finish complex geometries and surfaces that can be difficult to access.

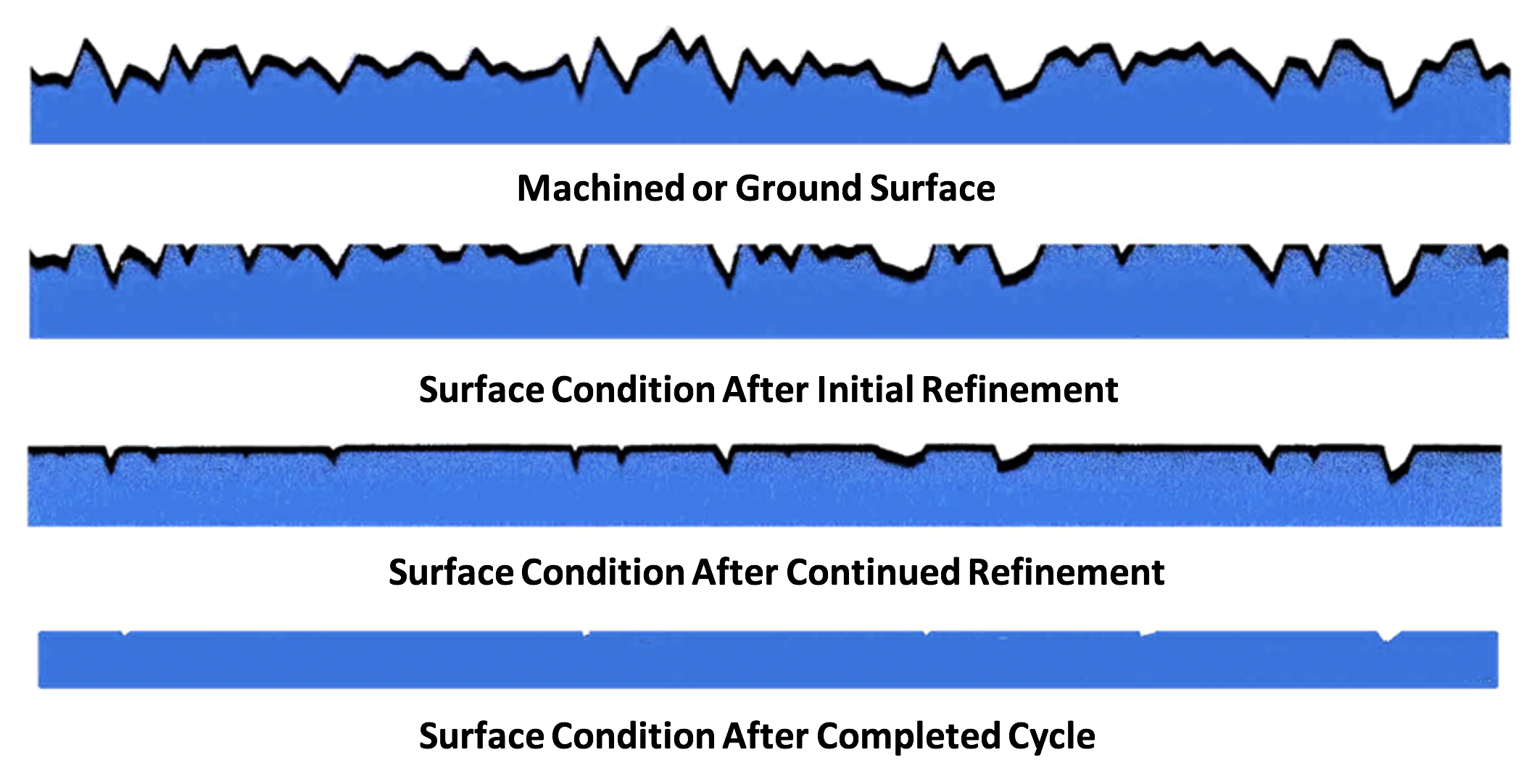

The process is designed to remove the peaks on the surface and allow the valleys (or low areas) to remain. The valleys will still retain oil at the wear surface interface, but will not have the high peaks that increase friction.

The initial step of the process is referred to as the refinement or cut process: the chemistry reacts with the surface of the parts, forming an oxide. The chemical conversion of the surface to an oxidized state allows the soft oxide on the peaks to be mechanically polished away by the media, allowing the bare, exposed surface to be oxidized again—a process that can repeat several times.

As the mechanical finishing by the media continues, it wipes the soft oxide layer away at the peaks but does not affect the valleys on the surface. When the refinement process is complete, it will transition into a burnishing step, which neutralizes and removes the refinement chemical and produces a mirror-like, polished finish on the product. (See schematic illustration below.)

Alloys That Can be Processed

- Stainless Alloys

- Low Alloy Steels

- Carbon Steels

- Super Alloys: Inconel & Waspalloy

- Aluminum

- Titanium

- MIM